About_us

EarthAid Inc. CEO

Japan Society of Comprehensive Medicine Auditor

Yuya Shimasaki

Promoting healthful food and culture through organic cultivation and additive-free manufacturing, contributing to people’s well-being.

Earth Aid inc. was founded in 2012 as a manufacturer of ‘nuta’ a garlic leaves paste, which is a traditional seasoning in Kochi Prefecture. Since the garlic leaves ‘nuta’ was a product with a strong character as a luxury item, at the time of its establishment, we were developing the product with “taste” as our top priority.

We discovered in the course of our business that:

- the food tastes better when no pesticides or chemical fertilizers are used;

- the food tastes better when no chemical additives are used in the production process; and

- when employees and their families continue to eat additive-free and organic food, their mental and physical health improves and immune disorders and lifestyle-related diseases are also cured.

In other words, we have experienced firsthand the truth that “when you pursue deliciousness, you will arrive at health and happiness. We would like to share this knowledge and culture not only with our employees and their families, but also with various people as part of our social mission. We want to share our knowledge and culture not only with our employees and their families, but also with people in other countries, so that they can enjoy products that we can safely feed to our family and friends. We hope that we can help them lead vibrant lives and realize their dreams and hopes.

In order to realize such a healthy and sustainable community, all of our farms have been certified as organic farms since 2013, and we have been working to produce organic vegetables. In our food production plants, we do not use synthetic detergents or chemical disinfectants so as not to destroy the natural ecosystem, and we are committed to reducing our environmental impact so that we can be a model case for a recycling-oriented society.

Through the provision of healthy food and food culture, people who have a relationship with us can become beautiful and healthy in body and mind, and can devote themselves to work, play, love, and help others. We want to pass on such a happy and vibrant society to our children’s and grandchildren’s generations. That is our desire.

Commitment to Agricultural Production

1. control weeds – green manure

How do you control troublesome weeds without using any herbicides outside of the growing season? The answer is to “use poison to control poison. The answer was to “control weeds with weeds,” using a technique called “green manure,” in which grass and legume plants are grown without any space between them, leaving no room for other troublesome weeds to grow. The fertilizer is then plowed directly into the fields without being harvested, where it decomposes completely in about two months due to bacteria in the soil, eventually becoming the most ideal natural organic fertilizer for the vegetables.

2. control sunlight – shading

We don’t want to use chemicals like anti-cancer drugs that also kill normal cells. We take the same view with regard to cultivation. Herbicides only work on certain weeds and are harmless to the vegetables we want to grow. We believe that such a convenient story is impossible. How do we physically control the weeds instead of chemically? The answer was shading. We thoroughly shade the garlic leaves so that only the garlic leaves are exposed to sunlight. We do this by hand, one by one, with a lot of care and attention. All for the sake of health and good taste.

3. temp control – low-temperature harvesting

Compared to garlic, garlic leaves is rich in vitamins A and C and polyphenols. It is a green and yellow vegetable that can truly be called “beauty garlic,” but like acerola, it is characterized by rapid damage and is rarely distributed even today. Therefore, the challenge is how to deliver it to customers without losing its nutritional value and taste. The optimal temperature for storing leafy greens is 0°C. We solved this problem by harvesting at dawn in the middle of winter when the temperature is close to 0℃. Our uncompromising work ethic results in high quality.

Commitment to Food Processing

1. high freshness freezing – quick freezing

How could we deliver the freshly harvested taste of garlic leaves to people in other regions? We chose quick freezing using a liquid freezer as a method to preserve the fresh taste of organically grown garlic without using preservatives or chemical seasonings. Plants live in refrigerated conditions, depleting their vitamins and sugars. By freezing the plants immediately after harvest, the nutritional value, taste, and color of the freshly harvested produce can be maintained, and the produce can be stored for a long time.

2. low-temperature cooking – mellow

How can we create processed products without losing the fresh and appetizing aroma, flavor, and bright green color characteristic of garlic leaves? We solved this problem by thoroughly lowering the temperature not only during harvesting but also during cooking to reduce oxidation and chlorophyll degradation. Using petroleum-derived flavors and chemical seasonings is the easiest way to increase the company’s profits, but as organic vegetable growers, we take pride and will in our products. It’s not just about taste, it’s all about the safety, health, and smiles of our customers.

3. additive-free ingredients – Scrutinize

Based on our philosophy of “providing happiness to our customers through healthy food,” we believe that even if the main ingredient is garlic leaves organically grown on our own farm, it is meaningless if the other ingredients are not of the same quality. We select carefully selected ingredients for processing not only for their taste and aroma, but also for their health and beauty. In addition, we do not use any food additives or processing aids that are not required to be labeled during the manufacturing process.

Commitment to the sixth industry

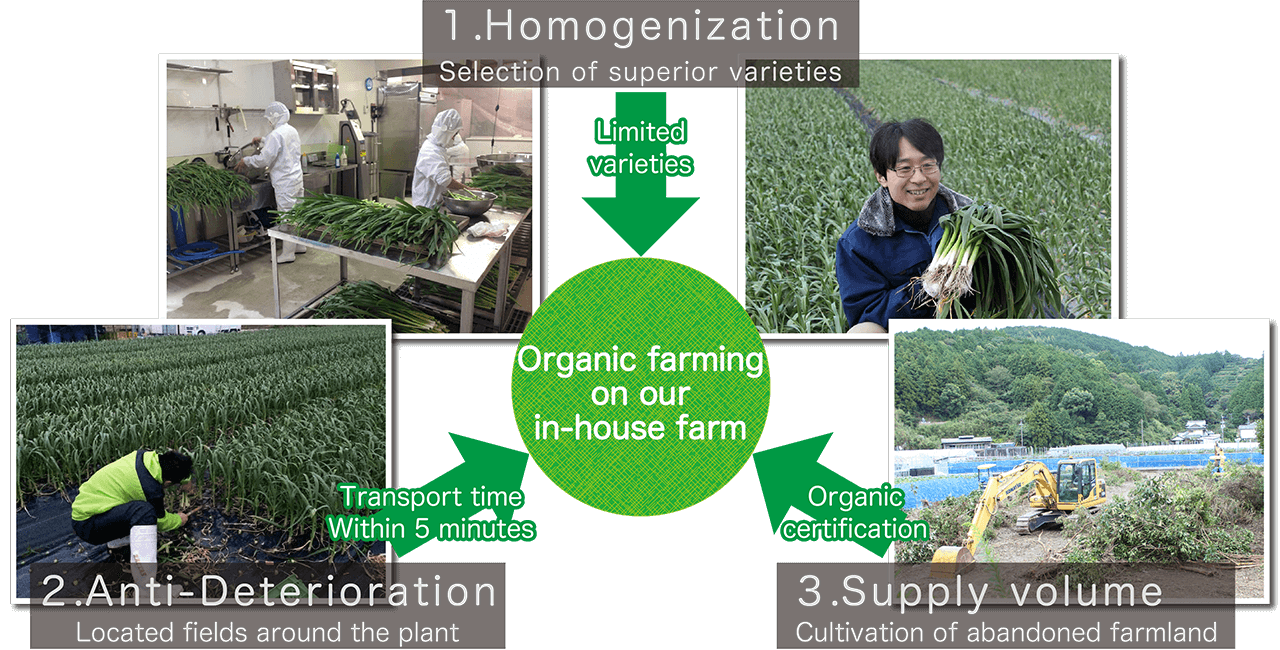

We want to make the best garlic leaves ‘nuta’ and impress our customers! To achieve this, we wanted to obtain the “best garlic leaves” at any cost! In order to achieve this goal, we finally chose to enter the agricultural industry. Our initial plan was to purchase garlic leaves from farmers and focus on food production. However, we were faced with three major problems.

1. Different farmers have different varieties of garlic leaves and different ways of growing it, resulting in differences in taste and aroma.

2. Garlic leaves is damaged quickly, so if the growing area is far away, the taste and aroma will deteriorate during transportation.

3. All farmers in the prefecture are small in scale, and it is impossible to purchase in large quantities.

In addition to these three issues of “1. homogenization, 2. prevention of deterioration, and 3. supply volume,” we found that cultivation using chemical pesticides and fertilizers resulted in a poor taste and increased pest damage. In other words, the need for “organic cultivation” to ensure stable mass production of “impressive taste” was the fourth issue that came to the fore.

We thought that the quickest way to solve these four problems collectively was to produce the products ourselves, and we worked to solve the problems using the following methods.

Leaf garlic deteriorates the fastest in terms of freshness, losing much of its aroma and nutritional value within a day of harvesting. Therefore, we have concentrated the fields within a 3 km radius of the processing plant, and achieved an overwhelmingly high level of freshness by processing garlic at high speed, from harvest to processing in one hour, and from processing to freezing in less than two hours.

Adding more intermediaries in the process from harvest to production does not improve the taste, increase the content, or increase the nutritional value of the product.

On the contrary, repeated transportation and unnecessary packaging damage the product and greatly reduce its quality.

Our basic philosophy is “to provide happiness to our customers through healthy food,” and our honest pursuit of health and high quality has led us to these sixth industries. The reason for the sixth industry is not because it is a fad or a trend, but because it is one way to realize our philosophy.

Company Information

| Company Name | EarthAid inc. |

|---|---|

| President & CEO | Yuya Shimasaki |

| Established | August 2013 |

| Headquarters | 2622 Uranochi Nishibun, Susaki City, Kochi Prefecture, Japan |

| Contact Information | Phone:+81-889-59-2248 (Japanese language only) Email:home@earthaid-tosa.com |

| Business Hours | Weekdays: 8:30 AM – 5:00 PM (JST) |

| Main Business Activities |

・Production of organic vegetables and production and sales of processed foods using organic vegetables ・Lectures on nutrition education based on dietetics, health seminars, and anti-aging ・Design, production, and planning and management of websites, online stores, and sales promotion tools |

| Certifications |

・Organic JAS certified business (EOAA Ehime Organic Agriculture Research Association_392061001) ・Ministry of Economy, Trade and Industry (METI) Certification for Excellent Health Management Corporations (Small and Medium Sized Corporations Division) ・Kochi Prefecture Work-Life Balance Certification: Certified as a Healthy Management Company ・Kochi Prefecture Industrial Promotion Plan Regional Action Plan Certification ・Kochi Prefecture Certified Eco Farmer (No. 762016) |

| Awards |

・2014: Kochi Prefecture Local Product Grand Prix Encouragement Award (for three types of Garlic leaf Paste) ・2015: Chef Masayuki Okuda Special Award at the Seasoning Championship 2015 (for Genovese-style Sauce) ・2023: Grand Prize Winner at the Kochi Delicacies Awards 2023 (for Carpaccio-style Sauce) |